Application of Statistical Techniques in Maintenance

In an increasingly competitive industrial environment, companies are compelled to optimize their maintenance processes in order to reduce costs and increase equipment availability. An effective way to achieve these results is by applying statistical techniques in maintenance activities.

By collecting and interpreting historical data on failures and operating times, more accurate and efficient decisions can be made. Statistical analysis allows the identification of failure patterns and curves, the estimation of component life cycles, and the determination of optimal intervals for inspections or repairs.

Examples of methods used:

- Reliability analysis – allows the identification of failure modes, whether we are dealing with random failures or advanced wear. It enables us to estimate the lifetime of components and equipment so that spare part requirements and repair activities can be planned correctly.

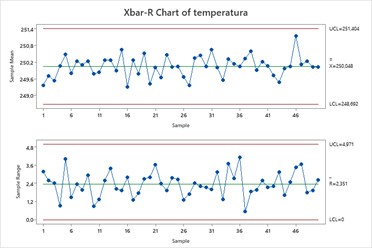

- Statistical Process Control (SPC) – by applying SPC, critical parameters (temperature, vibrations, pressure) can be monitored and deviations detected before equipment failure occurs.

- Correlation and regression analysis – used to establish the relationship between operating conditions and the failure rate.

- Failure forecasting – statistics can be applied to develop predictive models for equipment failures based on historical data and relevant factors such as operating hours, temperature, or vibrations. This allows for more efficient preventive interventions and better resource planning.

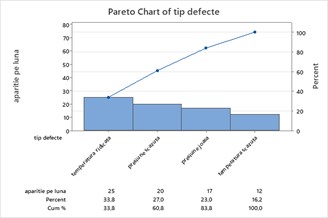

- Root cause analysis – statistical methods such as cause–effect analysis or Pareto charts can be used to identify and prioritize the resolution of causes or losses. These tools help direct our efforts so that resources can be allocated more effectively.

In conclusion, the application of statistical analysis in maintenance can bring numerous benefits, including the optimization of maintenance schedules, cost reduction, and improvement of equipment performance.