Preventive Maintenance: The Hidden Driver of Product Quality

Preventive maintenance is not just a maintenance activity, it is an integral part of the Quality Management System.

Preventive maintenance means performing regular inspections, replacing worn components and calibrating equipment before failures occur. Its goal is to keep equipment within operating parameters and to prevent major breakdowns.

How it influences quality:

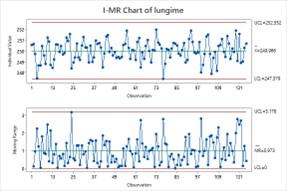

- Reducing process variation

- properly maintained equipment operates stable, with fewer deviations from nominal parameters.

- as a result, the production process is stable, products are more uniform and the risk of rejections is reduced.

- Preventing hidden defects

- minor failures (wear, vibrations, misalignments) can affect equipment accuracy without stopping production.

- through preventive inspections, these issues are detected before they generate nonconforming products.

- Ensuring traceability and compliance

- in regulated industries (automotive, medical, aerospace), preventive calibration of measuring instruments is mandatory to ensure that quality checks are accurate.

- Increasing customer confidence

- a consistently high-quality product, resulting from a stable production process, strengthens the company’s reputation and reduces the number of complaints.

By preventing variations and defects, preventive maintenance ensures stable processes and compliant products, supporting the fundamental objective of any company: consistent quality at reduced costs.