Process stability

Process stability in SPC (Statistical Process Control) is the critical element to ensure the quality of products and services. It indicates that the process variation is normal and predictable, in other words we know with a high probability where the future values will be.

Through continuous monitoring and the implementation of corrective and preventive actions, companies can ensure that the products delivered to the customer comply with the requirements and specifications, thus eliminating the risk of complaints and financial losses.

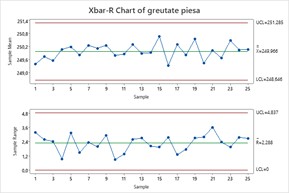

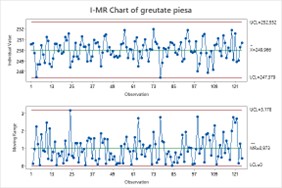

The Control Chart is the fundamental tool used to monitor and analyze in real time the variation and localization of production processes, offering a visual and statistical means of interpretation being composed of:

- the central line that represents the mean of the process

- the Upper and Lower Control limits of the process, representing the statistical limits within which the process should have variability

- data points representing the measured values

In order to achieve and understand the stability of the process, it is necessary to go through several steps:

- the correct collection of data, by identifying the characteristic/parameter to be measured, establishing the sampling method, establishing the number pieces from the sample, ensuring the correctness of the measurements in advance through the MSA (Measuring System Analysis), correct recording of the data according to the plan

- the correct selection of the Control Chart according to data types and/or if there is grouping or not

- interpretation and analysis of process stability for variation and localization

- if the process is not stable, having values outside the control limits, factors causing this must be identified and improved (Machine, Material, Method, Man, Environment, Measurement) through specific actions or improvement projects

- process monitoring through Control Charts must be continuous, especially after the actions have been implemented to demonstrate the effectiveness of the implemented actions

The continuous evaluation of process stability helps companies to intervene preventively to minimize variability, which reduces the risk of producing defective products, offers constant quality for customers, thus increasing the organization's competitiveness.