- Home

- About Us

-

Consulting

- Management Systems

- Increase production capacity

- New Project Implementation (NPI)

- Logistics

- Suppliers' chain and Supplier development

- Quality improvement

- Plastic materials and process optimization

- Performance assesment

- Maintenance System implementation

- Implementation of Preventive maintenance

- Implementation of Autonomous maintenance

- Implementation of preventive maintenance for Robotics

- Case Studies

- Resources

- Training

- Digitalization

- Articles

- News

- Team

- Jobs

- Contact

Reverse FMEA

R-FMEA is a method of reviewing at each production station/step the potential failure modes identified in P-FMEA. It is also called "Go and See" PFMEA.

The goal is to detect potential failure modes not previously identified in P-FMEA. It is also aimed to confirm that the potential failure modes already identified have implemented control methods, preferably as close as possible to the production station / step where the defect occurs.

Important activities:

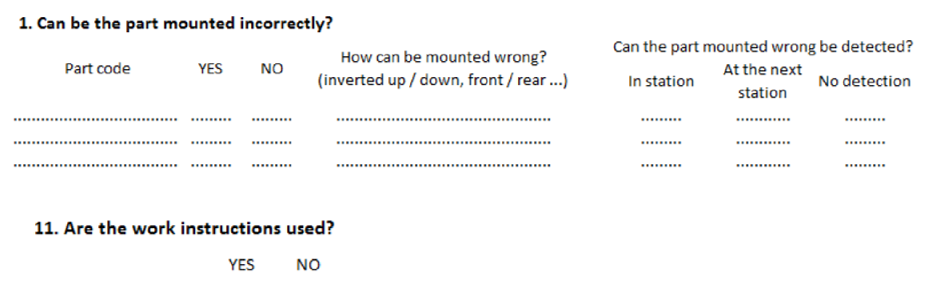

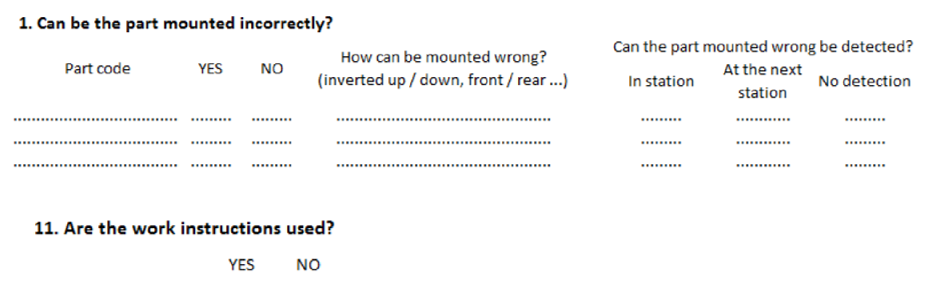

Evaluation of the additional questions (11 of the previous examples) will lead to further revisions of the P-FMEA or process corrections depending on the answers.

The final evaluation and the framing of the P-FMEA is done according to the chosen criteria and the answers to the main questions (1 of the previous examples) taking into account the place where the detection can be done – at the station where the defect occurs, at a next station or without detection.

The goal is to detect potential failure modes not previously identified in P-FMEA. It is also aimed to confirm that the potential failure modes already identified have implemented control methods, preferably as close as possible to the production station / step where the defect occurs.

Important activities:

- Creating an audit plan (annual) for the products and production steps that need to be analyzed

- Definition of multidisciplinary teams (Engineering, Quality, Production, Maintenance...) considering whether it is possible to include a person from outside the analyzed process (fresh eyes)

- Carrying out audit according to planning

- Record observations, as detailed as possible for further analysis

- Realization and implementation of action plan according to observations

Evaluation of the additional questions (11 of the previous examples) will lead to further revisions of the P-FMEA or process corrections depending on the answers.

The final evaluation and the framing of the P-FMEA is done according to the chosen criteria and the answers to the main questions (1 of the previous examples) taking into account the place where the detection can be done – at the station where the defect occurs, at a next station or without detection.