Article list

Six Sigma in livestock farming

Many of us have heard about farms, stories about traditional diets, about long forgotten recipes in an actual kitchen increasingly assault by "flavor of the supermarket". Farms are a complex area, with a major impact on human health and the environment, on the rural economy and society as a whole.An example of a successful project in a farm is using Six Sigma is "Increase of integral milk sales". In first phase, Define, was found that in the shop from the village some customers talk that "the...Read this article...

Six Sigma in agricultural farms

Agriculture is the science, art or practice that deals with the production of plant and animal food, fiber or useful materials through the systematic cultivation of certain plants.In agriculture, there are many parameters that can be measured: Soil type, previous plant, crop rotation, fertilizer application, tillage, seed treatment, the optimal time of sowing, optimal seeding density, crop maintenance works (irrigation, mechanization), storage and preservation, etc. Only food mentioned in the...Read this article...

Six Sigma in passenger transport

In the current competitive market, many transport companies offer the same services of person transport. The main distinguishing factor in front of users is, most of the time, the quality of these services. Six Sigma can help improve the quality in person transport.Six Sigma is a data driven process improvement methodology based on DMAIC cycle (Define – Measure-Analyze – Improve – Control). Examples of measurable indicators for the specific activity of transport could be: time...Read this article...

Six Sigma in purchasing

Acquisition process, like any process, is composed of a sequence of operations that transform inputs into outputs and adds value. When we talk about entries we think of course about suppliers and performance of their products, including their evaluation. Evaluating is ISO 9001 or 16949 IATF requirement.Six Sigma is a 5 steps methodology (Define - Measure - Improve - Control) and can help in improving the acquisition process. Examples of measurable indicators in acquisitions can be: the minimum...Read this article...

Six Sigma in courier services

Six Sigma can help improve courier services that provide transport activities, parcel transport, that means transport and postal activities. Examples of measurable indicators can be: rate of delays in delivery, number or rate of human error, income and expenses on cost centers and cost, fast reaction times.For example: A Six Sigma project could be "Increase customer satisfaction". The key indicator which give the performance of the process is index of customer satisfaction (S) and it is...Read this article...

Six Sigma in retail

According with Pareto's Rule (80/20) in retail is not wrong to say that 80% of sales come from 20% of your inventory. Starting from this principle we can think about how to apply continuous improvement in retail sales. Can be used also Six Sigma methodology.Read this article...

Six Sigma in sports

Few people know that Bob Hayes went under 10 seconds in the 100 meters race at the Olympic Games in Tokyo in 1964. The record now is 9.58 seconds which was run by Usain Bolt. Also in sport we can use improvement techniques like Six Sigma.An example of a successful project using Six Sigma was "Improving running time in the 100 m / Athletics". The key indicator which give the performance of the process and choose to be improved is running time until the completion (T).Read this article...

Six Sigma in transportation

Examples of measurable indicators in transport activity can be: average transport distance (D); loading of truck (G%); specific cost of the delivery by example cost per km (p); tonnage per axle (T); productivity (P), etc.Here is an example of successfully using Six Sigma: “Increased productivity of transportation”. The key indicator which give the performance of the process is P / Productivity (tons x km/tons capacity). This indicator should be as big as possible and it is critical...Read this article...

Six Sigma in the textile industry

For the textile industry, quality of is essential and diversity of products is the same a critical concern.The textile industry is an area with lots of variations and defects in manufacturing processes. So, applying Six Sigma is a must for this area.An example of a successful project using Six Sigma is "Reducing the variations that occur during the seam of perimeter”. The key indicator which give the performance of the process is seam allowance, which is the distance from the seam to the...Read this article...

Six Sigma in logistics

Here is an example of successfully using Six Sigma: “Reducing stopping lines time caused by logistical problems”. The key indicator which give the performance of the process is Y% - the percentage of stops caused by logistics errors reported to total available (Td). This indicator should be as small as possible and it is critical for customer satisfaction (delivery time) and for cost reduction in the same time.In Define is identify and study the process and select the team that will...Read this article...

Six Sigma in the hotel industry

Here is an example of successfully project using Six Sigma used to improve activity in hotels. Project name is “Increase customer satisfaction”. The Define was studied process (process map), was established the team to work on this project and have listened to the voice of customers, VOC. The key indicator which give the performance of the process was choose “Customer satisfaction” noted with Cs.A questionnaire with 10 questions was used and data were collected for 2...Read this article...

Fault Tree Analysis

Fault Tree Analysis was developed by Bell Telephone laboratories in 1962 for U.S. Air Force and later adopted and extensively used by Boeing Company.Fault Tree Analysis is in fact a technique by which many events that interact to produce other events can be related using simple logical relationship. This technique follow a top - down structure and represent graphical model of the pathways within a system between basic events that can lead to a foreseeable loss event (or a failure) referred to...Read this article...

Theory of Constraints (TOC) – Diagnosing and improving the organizational system

Theory of Constraints (TOC) is, in short, a suite of management concepts developed by Dr. Eliyahu Goldratt in his landmark book “The Goal”. It helps managers and senior leaders to decide:1. What to change2. What to change into3. How to cause and drive the changeDespite its name, the Theory of Constraints is not actualy theoretical, but rather helps in finding practical and effective solutions to complex and real business problems. The cornerstone of TOC is systematically...Read this article...

Triz - a systematic approach to enhancing and accelerating creativity

TRIZ is the Russian acronym for Theoria Resheneyva Isobretatelskehuh Zadach i.e., Theory of Inventive Problem Solving. It is based on 2 fundamental principles:1. There is a high probability that somebody, sometime, somewhere has already solved your problem or a problem similar to it; enhancing creativity means finding that solution and adapting it to your current problem2. Never accept compromise when dealing with contradictions. Resolve them.TRIZ was developed by G.S. Altshuller and his...Read this article...

Six Sigma in healthcare

Six Sigma enables hospitals and other medical institutions to improve patient safety and satisfaction by improving both medical and administrative performance.A hospital in Holland, was experiencing long delays of planned surgery and therefore patient dissatisfaction, due to inefficient use of the Operating Theaters. As this situation was a major concern, the hospital doctors and the management team were searching for a solution. As Operating Theaters (OTs) are expensive and capacity-limiting...Read this article...

Six Sigma in maintenance

Six Sigma is a data-driven process improvement methodology and uses DMAIC (Define-Measure-Analyze-Improve-Control) as a project management cycle.It started by being applied in production processes and is currently used in all business sectors, including telecommunications, financial services, maintenance activities, logistics, human resources and public services.Here is an example of the successful use of Six Sigma methodology to meet and even exceed Critical Customer Requirements...Read this article...

Lean in auto service

Lean is a business and process optimization philosophy based on 5 principles: define value, map the value stream, make value flow, establish pull and continuously improve to perfection. Applying lean reduces waste and enhances people creativity and engagement.It was first applied in car manufacturing at Toyota (Japanese car manufacturer) as TPS (Toyota Production System) and subsequently spread to all business sectors, including industrial services, financial services, logistics, human...Read this article...

Six Sigma in marketing

Six Sigma enables companies to improve marketing’s strategic, tactical and operational processes: let us take as example improving the quality of leads generated by a company website.A company used its website as a lead generation machine, allowing visitors to download whitepapers and software demonstration copies (over 200,000 per year). For each downloaded item, a lead was sent to the company’s call center – however, the CEO was frustrated with the low conversion rate (CR)...Read this article...

Six Sigma in insurance

Six Sigma enables insurance companies to improve customer satisfaction by reducing the Lead Time (LT) for claim resolution.An insurance company, active in the Property and Casualty (P&C) business was losing market share as a result of an increasing number of defecting customers (customers leaving the company). As this situation may force the company out of business, the CEO and the management team were searching for a solution.Read this article...

Six Sigma in education

Six Sigma enables schools, universities and other educational institutions to improve student knowledge, skills and satisfaction by improving both educational and administrative process performance.A US University, was experiencing difficulties and long delays in defining and approving the new course and curriculum, resulting in both professors’ and students’ frustration and dissatisfaction. As this situation was a major concern, the university management team commenced searching...Read this article...

Transport Cost Reduction Methods

Transport and distribution are the circulatory system of any business, with direct implications in supplier performance to customers, being some of the critical points in Logistics and are some of the measurable indicators which show the ability of a supplier to render quality and competitive services.Transport costs take 5-10% from the capital circulated by a company meaning they have an important impact on the final profitability of the products and services sold. From this amount, for road...Read this article...

Steps for Warehouse KANBAN/EKANBAN Implementation

KANBAN is a LEAN supply and organizing system for materials. KANBAN system represents a way of ordering based on an order signal, considered start of the order, based on which a pre-established quantity is delivered. There is physical KANBAN where the order signal is a physical object (card, box) and there is EKANBAN where the signal is an information sent through and ERP system between customer and supplier (label/scanning).Read this article...

Stock Value Reduction

In a constantly changing market, in an extremely flexible business environment in terms of customer demand and preferences in which the need for research and development of new products is increasingly important, there is a need to have available as much of business cashflow.In general, in industries, stocks (of raw materials, sub-assemblies and finished products) represent from 45% to 75% of the working capital of companies. Hence the need for an efficient control of the stock level.Reducing...Read this article...

Benefits and Implementation Steps of Scanning and Control Systems

Materials’ scanning systems represent the natural tendency of all industries in their attempt to control the level and accuracy of stocks as well as corectness of transfer and transformation operations of materials.Scanning systems are critical for industries using a large number of raw materials and producing a large number of finished goods. Without scanning systems storage and handling of a largu number of materials becomes very slow and subject of human errors. Implementation of...Read this article...

Warehouse Storage Space Optimization

Storage space defining and dimensioning is a real challenge for any type of business. Storage space defining has to take into consideration the materials that will use the space (type, dimensions, packaging), the types of procurement and deliveries, the type of production and the resources both material and human available. Storage space dimensioning has to take into consideration the defined type of warehousing (with or without safety stocks), type of production (PUSH or PULL) as well as long...Read this article...

Key Elements in Designing Materials’ Warehouses

Designing materials’ warehouses means arranging a space (existing or which will be built) to efficiently and profitably serve for storage and all warehousing operations of materials stocks (raw materials, subassemblies and finished goods).Advanced planning of operations is done by checking a company’s histroy and experience in materials warehousing, taking into consideration materials specifics (dimensions, stacking possibilities, dangerous materials, etc.) space constraints,...Read this article...

VSM - Value Stream Mapping

VSM is a tool Lean value stream mapping within an organization, areas, sections or production line, can approach suppliers, customers or other factories from the group.VSM is a visual representation of the process flow and the information within it, information about indicators of production, quality, maintenance, process, visual communication tool able to identify and support the elimination of losses.By a clear picture, as long as it is real, VSM underline the problems, and help identify...Read this article...

Kainzen - Continuous Improvement

Kaizen is a concept that teach us how we can improve by small but constant steps, the professional activity of employees or a company, but also with an impact in personal life.Kaizen is a Japanese word, which means "good change", change that if is supported leads to continuous improvement of productivity, level of quality, commitment and motivation of employees, which can make the difference in the development of a company or her disappearance.Read this article...

OEE

One equipment 100% efficient should produce 100% of the time available, 100% in the designed parameters, and 100% conform parts with the specifications.To measure that there is an indicator called OEE, which is an indicator of performance equipment, which follows the overall effectiveness of the equipment. To calculate OEE, will take into account the availability of equipment, equipment performance and quality process results.Read this article...

Teamwork

According DEX, a team is a group of people lead by a leader, who work in the same time to a task or common action. To accomplish this teamwork, all group members need to cooperate to achieve the same objectivesFrom the frame point of view for teams, they may be homogeneous or heterogeneous. By homogeneity, the team will be more easily aligned with the objectives and way of working, but a heterogeneous team, even if you have conflicts, offer multiple perspectives to problems approach.Read this article...

Distribution Normality

In probability theory, the normal distribution is a very common distribution.Normal distributions are important in statistics and are often used in industry, natural and social sciences to represent real random variables whose distributions are not known. Several very important statistical tools rely on the assumption of normality. For this reason, it is essential to validate the assumption for continuous variables so that we can choose the right (Six Sigma) tools.The normal distribution is...Read this article...

Six Sigma applied in Telecommunications

Six Sigma is a data driven process improvement methodology based on DMAIC project management cycle (Define-Measure-Analyze-Improve-Control).It was first applied in manufacturing and it is currently used across all business sectors, including telecommunications, financial services, logistics, human resources and public services. Here is an example of successfully using Six Sigma to satisfy and even exceed Critical Customer Requirements (CCRs), related to resolution of a customer request in a...Read this article...

Six Sigma in banking

Six Sigma is a data driven process improvement methodology based on DMAIC project management cycle (Define-Measure-Analyze-Improve-Control).It was first applied in manufacturing and it is currently used across all business sectors, including financial services, logistics, human resources and public services. Here is an example of successfully using Six Sigma to satisfy and even exceed Critical Customer Requirements (CCRs), related to issing a Debit Card, in a Bank.Read this article...

Six Sigma in metallurgy

Six Sigma is a data driven process improvement methodology based on DMAIC cycle (Define – Measure-Analyze – Improve – Control). This methodology can be applied successfully in Metallurgy.Here is an example of successfully Six Sigma project used to decrease number of ball bearings blocking in stands in a rolling mill. The ball bearings used in stands of the mill have diameters reaching nearly 1 meter, are very expensive and their replacement times exceed 4 hours. The key...Read this article...

Six Sigma in the oil industry

Six Sigma is a data driven process improvement methodology based on DMAIC cycle (Define – Measure-Analyze – Improve – Control). This methodology can be applied successfully in oil industry.Examples of measurable indicators specifics of this industry can be: tilting the geologic layer, saturation pressure, viscosity (under standard conditions), density of oil, oil type (waxy or not-waxy), type of water from deposit (salinity), porosity of the basic rock, etc.Here is an example...Read this article...

How Minitab helps

MINITAB is a statistical software package developed at Pennsylvania State University and which became one of the most used worldwide. The software is intensively used for statistical applications such as SPC, MSA (typical for the automotive industry but not only for this) Six Sigma projects, Reliability (in maintenance) and graphical data interpretation.Read this article...

Reverse FMEA

R-FMEA is a method of reviewing at each production station/step the potential failure modes identified in P-FMEA. It is also called "Go and See" PFMEA.The goal is to detect potential failure modes not previously identified in P-FMEA. It is also aimed to confirm that the potential failure modes already identified have implemented control methods, preferably as close as possible to the production station / step where the defect occurs.Important activities:Creating an audit plan (annual) for...

Read this article...

SIPOC

SIPOC diagram is a visual representation of a process map of the high-level; SIPOC includes process but also inputs and suppliers and the left and outputs and customers from process on the right. SIPOC is the diagram that helps a team to draw the process map and identify key indicators.The common elements to all processes are: Suppliers, Inputs, Process, Outputs and Customers.Read this article...

Objectives management

Management objectives or management by objectives is an instrument that consists in setting goals, planning of them, control and evaluation.When we talk about goals they may be targets of quality according to standards, can be technical and economic indicators of companies, or the indicators for production, quality, safety, etc.Read this article...

Process map (Flow chart)

A Process Map or a flowchart is a picture of the separate steps of a process in sequential order. Also called: process flowchart or process flow diagram.Elements that may be included in a Process Map are: sequence of actions, materials or services entering or leaving the process (inputs and outputs), decisions that must be made, people who become involved, time involved at each step and/or process measurements. An example of high level Process Map is:

The process described can...

Read this article...

CTQ (Critical to quality)

Tagucci said “If you cannot measure a customer requirement, you will not know if you`ve improve it”.Starting from this affirmation we have to think how to transform the customer's voice into a measurable indicator. CTQs are the key measurable characteristics of a product or process whose performance standards or specification limits must be met in order to satisfy the customer. Typically, a CTQ must be interpreted from a qualitative customer statement to an actionable, quantitative...Read this article...

Voice of the customer (VOC)

Voice of the Customer (VOC) captures how customers feel about their experience with a business, product and/or service.The concept of “putting the customer first” is based on the fundamental assumption that most things done to increase customer satisfaction will have a favorable downstream effect on the business.Read this article...

The purpose of graphical analysis

The use of the graphic method of presenting statistical data is done in order to reproduce in a simple, attractive and suggestive form the essential features of the processes studied in certain conditions of time and space.Starting from the well-known proverb "A picture is worth a thousand words", graphical analysis has the possibility to concentrate a large amount of information in a minimal space.From a theoretical point of view, for the same statistical data there are several possibilities...Read this article...

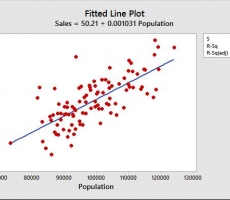

Regression

In statistics Regression is a statistical process that estimates relationships between variables. Regression models involve the following terms:Independent variables, x;

Dependent variables, Y.

The equation Y = f (x ) is converted to numbers and allows us to find the required level of x in the expression for a given Y.This way when the customer changes to a different Y, the new value of the variable x can be quickly identified so that the new requirements are met.Regression helps us...

Read this article...

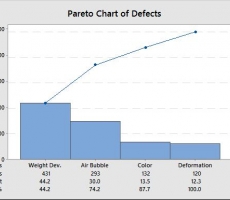

Pareto

Pareto chart is a type of diagram that contains both bars and a line graph, where individual values are represented in descending order by bars, and the cumulative total is represented by the line. The purpose of Pareto chart is to highlight the most important factors from a set of data and to allow prioritization.The name is coming from Vilfredo Pareto, an Italian economist who studied the distribution of wealth in different countries. He concluded that 80% of income in Italy was received by...

Read this article...

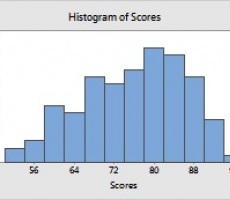

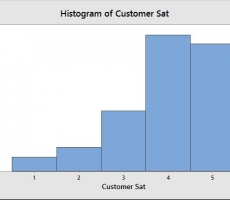

Histogram

A histogram is a graphical representation of the distribution of numerical data. This can be used when working with a lot of data. The purpose of a histogram is to graphically summarize the distribution of a data set.In fact, this representation is a specialized version of the bar chart used in excel. The possible values of the selected variable are represented on the horizontal axis. Frequencies are represented on the vertical axis.Individual data are grouped into classes so that we get...Read this article...

PDCA (plan, do, check, act)

PDCA was named for the first time in the 30`s by Walter Shewhart, who discussed about this concept in his book “Statistical Method from the Viewpoint of Quality Control”.PDCA cycle have connections and is pretty the same as other problem solving methodologies, simple or more complex, like 8D, DMAIC from Six Sigma. Even recent changes to ISO 9001 process-based orientation chapter came with new concept risk-based thinking - closely linked with the PDCA.Read this article...

Statistical Process Control with Q-DAS qs-STAT

Statistical Process Control (SPC) is a quality control method that uses statistical methods. It is used to monitor and control the processes. Principal elements of SPC are control chart and process capability study.Read this article...

Measurement System Analysis with Q-DAS Solara

MSA is an experimental mathematical method that determines how much of the total variation observed is due to the measurement system itself. It helps us to determine the ways in which a measurement system needs to be improved. Measurement System Analysis (MSA) is a first step that should precede any decision, including the use of Statistical Process Control.Read this article...

QFD

QFD, the English acronym for Quality Function Deployment, is a system for designing a product or service based on customer requirements that involves all members of the manufacturing/supplier organization.The system is explained by its very name:Quality = meeting customer requirementsFunction = what needs to be doneDeployment = Who, how, when will doQFD was implemented for the first time in Japan, at the Kobe Shipyards belonging to the Mitsubishi company - between the years 1977 - 1984,...Read this article...