Article list

Three best strategies of staff retention in 2021

Staff turnover is expensive. In general, it costs us 3 times more to hire a new person in the department than to retain an employee.About 50% of employers consider talent retention to be one of the biggest challenges they face, and around 40% consider recruitment to be the biggest challenge for them during this period (sparkbay.com).

If salary increases are one of the main reasons for accepting a new role in a new company, these increases do not play a major role in staff...

Read this article...

The assumed role - the premise of happy teams

Rapid changes, the need and the ability to constantly adapt to new technologies, which bring with them new needs of consumers, customers, bring a new perspective to the understanding of organizational structures and production processes.In this context, in Lean / Agile companies, roles are more important than jobs / positions. Why? They bring more flexibility being associated with flexible processes, they can be taken over by people with various functions (managerial or not), they enhance the...

Read this article...

Active listening and the success of a professional relationship

Our life revolves around relational structures: we relate to family, friends, co-workers, people on the street, in the store, we relate to ourselves. Relationships exist only in the context of communication. Without communication the relationship disappears. Communication can be healthy, fluid or on the contrary - it can be difficult, and as a result: the quality of the relationship depends on how well we communicate.The professional environment regulates, through communication policies, the...

Read this article...

The interpretation of the communicated message or active listening

Human communication, the process by which we exchange information with peers, is essential in the development of life, profession, in the relationships that we initiate, maintain or even interrupt. Communication involves a permanent transmission and reception of information, and when the permanence of these two processes is interrupted, communication disappears.The transmitted information is encoded in symbols (words, numbers, images, etc.), and decoded by the receiver, the one who receives...

Read this article...

The integration of new employees

According to the Society for Human Resources Development (SHRM), the integration of new employees is the process by which new employees adapt to the social and performantial aspects of the new job in an easy and natural way and acquire knowledge, attitudes, skills and behaviors appropriate for the actual activity within the company ”.In short, the integration of new employees is the process by which the company ensures that newcomers start their activity "the right...

Read this article...

ISO 9001 - The Challenge of Certificates

You have successfully completed the Quality Management System certification process and are the proud holders of an ISO 9001 certificate for your organization… one of the approximately 10,000 ISO 9001 certificates in Romania and one of the approximately 900,000 ISO 9001 certificates worldwide.Well done, congratulations… but as you can see you are not unique at all but just one “of the many”

What are you going to do next?

The answer to this question is the real...

Read this article...

Standardization - an important step in any organization. Why do we use it?

We all know that the basis for continuous improvement is standardization!In addition to making our work easier, it reduces losses, improves quality and safety at work, and helps us be disciplined.

Each of us wonders about the standards and goals of an organization as we cross its threshold.

The standard makes it possible to master the technical characteristics, to satisfy the customer, to validate the manufacturing methods, to increase productivity, offering a sense of security to...

Read this article...

Employees' benefits' system

The system of benefits offered to employees represents the indirect and non-cash compensations paid in addition to the salary package.The 2021 employer knows that the motivation, involvement of employees and their productivity depends on how appreciated and recognized they feel at work. At the same time, the employees link the appreciation granted to the package of benefits granted. The better it is adapted to their needs, the more they feel appreciated and respected.

To have the desired...

Read this article...

Professional development needs' analysis

- The starting point in achieving workplace efficiency -Identifying and analyzing professional development needs are processes through which companies harmonize their own needs and individual professional development needs in order to reach the maximum potential of employees and the organization.

The identification of training needs takes into account:

- The level of knowledge, skills, competencies that are necessary in order to achieve business objectives and maximum individual...

Read this article...

Leading the problem solving workshops

A problem is any deviation from standards or expectations that carries negative connotations.In everyday life, problems can lead to situations that cause us failure to achieve our goals.In business, problems can lead to low productivity, poor quality, high costs or even loss of customers.As with any methodology, there are obstacles in the process of solving problems. Among them we could list: Lack of problem solving tools, lack of time, resources, fear of failure or failure, lack of teamwork...Read this article...

Maintenance KPIs

If you want to achieve any goals in life - whether personal, group or organizational - then you need to know where you are going, how you will get there and how well you accomplish the tasks that lead you there. This also applies to maintenance work.Maintenance performance can be analyzed through key indicators (KPIs), which give us an immediate sense of direction, performance and perspective. Maintenance performance information is a source that can put you ahead of the competition. Modern...

Read this article...

QMS: The benefits of process based approach

All the standards used in the management of Quality Management Systems (ISO 9001: 2015 or IATF 16949: 2016) require and use the process-based approach according to the PDCA methodology.PLAN - the top management of the organization establishes the context and stakeholders, its scope and limitations, objectives and quality policy of the SMC. SMC processes together with the risks involved, the interactions between the processes, the objectives and the programs to achieve them are established.DO -...Read this article...

The focus of great mentors

Mentoring is that relationship that is formed between an expert and another person who sets goals within the mentor's field of expertise.The mentoring relationship does not imply a power ratio, the position of the mentor or the mentee being unimportant. According to the Harvard Business Review, 75% of the workforce in a professional setting says they need a mentor, while only 37% actually have one. We are used to mentoring relationships only when we think of junior colleagues who join us...

Read this article...

Top 3 performance indicators of staff recruitment and selection

In the competitive environment in which we operate during this period, the performance of human resources processes becomes a mandatory and defining topic in business decision-making processes.Although recruitment and selection of staff is still something that happens within many companies anyway, remaining unmeasurable processes, monitoring them brings visible benefits to the company and has a considerable impact in motivating HR specialists, giving them the opportunity to acknowlege the...Read this article...

Staff recruitment - the reinvented wheel

Staff recruitment occurred during World War II. CVs and recruitment agencies also appeared in the next decade. Since then and until 2021, many aspects of staff recruitment have improved, refined, refined, but can we say that something has changed in recruitment activities? The answer is no.However, with a simple internet search, you can find dozens of trainings, courses, workshops on staff recruitment. Do these courses and workshops reinvent the wheel ? Yes and no.

In terms of...

Read this article...

First Pas Yield vs Rolled Throughput Yield

Quality is the heart and soul of any production unit. And production means both productivity and efficiency of use of the materials used.Many companies aim, even through KPI (Key Process Indicators) at the company level, to reduce their costs in order to reduce prices or to be able to withstand competition in the market, but also to reduce their probability of delivering non-compliant products to customers.The first-pass yield (FPY), also known as the transfer yield, is an indicator of the...Read this article...

Process Engineer - Pilot of continuous process improvement

Immediately after the revolution, in that period of restructuring and nebulous in connection with the professional future, many engineers gave up the profession and started selling or went abroad after a better life.In recent years, with the return of economic growth that has revived the market, engineers have begun to be sought after again.Process engineers, the basic category in production, are among the most specialized engineers when it comes to execution technology but also when we talk...Read this article...

Case Study. Stratification in the selection of improvement projects

In problem solving, choosing projects by identifying the best opportunities in team actions often makes the difference between success and failure.Choosing too large an area can lead to loss of focus, unnecessary spending of resources and failure to meet proposed targets.To understand the mechanism for selecting improvement projects, let's take as a case study a company that produces cold-rolled stainless steel strips.From the data collected from the quality information system (ERP) it is found...Read this article...

Who is responsible for the OEE?

Identification of production bottlenecks is done using in-depth analyzes, provided by numerous reports, such as: job and operator performance, OEE, production cycle analysis, machine use and downtime history, which allow production managers to make decisions. objective and informed. Monitoring machine performance allows managers involved in production to analyze, interpret and make decisions based on the data received to maximize their efficiency. Relevant machine operating parameters are...Read this article...

What is Self-Maintenance and how does it help me?

Self-service is defined as a maintenance strategy in which machine operators continuously monitor their equipment, make adjustments and perform minor maintenance tasks on their machines. It is the first pillar of the TPM (total productive maintenance) strategy.An operator trained in self-maintenance means knowledge of routine tasks such as cleaning, lubrication and inspection.

Self-maintenance aims to reduce intervention times. Indirectly, the number of defects is reduced and the equipment...

Read this article...

Process capability and equipment reception

The capability of the technological process represents its ability to make parts with characteristics within tolerances.W. A. Shewart defines the ability of the process as its property to ensure a field of variability of a certain measurable characteristic smaller than the specifications.A stable technological process is capable if the natural spread obtained under known technological conditions and defined by the difference between UCL (upper control limit) and LCL (lower control limit) is...Read this article...

Application of statistics in Maintenance

It often happens to us that we have a lot of data collected in tables and that we have to interpret. An example is the recording of downtimes on different equipment.We all know that the analysis of data in tables is difficult to do and that is why graphical representations are desirable.

The MINITAB statistical software provides us with graphical and statistical tools that process this data in a form that is easy to analyze. I mention some of the most used: Histogram, Box Plot, Pareto, Time...

Read this article...

Benefits of implementing 45001

As we mentioned in the previous article, there are a number of real, measurable benefits in terms of implementing and carrying out the activity respecting the requirements of the ISO 45001 Standard.Thus, the key benefits of using the standard include:

Reducing incidents at work

Reducing absenteeism and staff turnover, which leads to increased productivity

Reduced costs of insurance premiums

Creating a culture of health and safety at work, employees being thus encouraged to take an...

Read this article...

Implementation of the new product - takeover in production

Project takeover in the operational area is a transition process initiated when a project is completed or nearing completion and enters series production. This transition of a project into production must follow the plan established with the terms and activities corresponding to the project management.The introduction of new products that consumers and customers require requires detailed information, time and dedicated resources from an organization. Companies that successfully develop and...

Read this article...

Who solves the problems?

Problems continue to arise so quickly that we find solutions and shortcuts to temporarily alleviate voltage points - so that we can move on to the next problem. In this process, we fail to eliminate the root cause of every problem that arises and we are trapped in an endless cycle that makes it difficult to find real solutions. Does it sound familiar?We all have problems that we face in our daily activity and life, it seems that there is never enough time to solve each one without facing...

Read this article...

Coaching in Six Sigma projects

Six Sigma is a complex five-step problem-solving methodology (Definition, Measurement, Analysis, Improvement and Control).From the beginning of the Six Sigma program, starting from the strategy approached by Top Management, listening to VOC (Voice of Customer) or VOB (Voice of Business), evaluating problems and prioritizing them, the coach is involved in opening the management horizons for choosing projects. Six Sigma.

Green Belt and Black Belt coaching is for many organizations an integral...

Read this article...

Lean in maintenance processes

Yes, Lean is also suitable for maintenance.Maintenance is considered an activity that contributes to improving the availability, efficiency and productivity of each piece of equipment. Several techniques have been used to achieve greater maintenance efficiency, among which we can find the Lean maintenance philosophy.This methodology allowed the prescription of appropriate Lean techniques to solve the main deficiencies of the maintenance function, obtaining important results and making the...Read this article...

We, the robots and their maintenance

Over time, man has built tools to make his work easier and more productive. They have been continuously improved and become more and more efficient. Each industrial revolution brought new tools and technologies. I called some of them robots.Brief history of the appearance of robots:1938 - the first attempt to make a robot in anthropomorphic design, by the American engineer Wenslei (Westinghouse Electric Manufacturing Co.)

1940 - the use of the first synchronous manipulators for the...

Read this article...

11.03.2021- ISO 45001 implementation deadline

Every day in the world, approximately 6300 employed people lose their lives either due to occupational diseases or work-related accidents, ie more than 1,000,000 lives / year.The list of tragic events at work in our country is, unfortunately, much too long, reaching a number of hundreds of such cases every year, which unfortunately puts us in the first places in the European rankings of this gender.All these accidents and illnesses, in addition to the undesirable effects on the people involved,...Read this article...

The importance of plastics

Plastics are a constant presence in everyday life. This is due to some advantages of these materials from which we can mention:pleasant appearance;

easy processing possibilities and relatively simple, productive equipment;

wear resistance and high portability;

accessible raw material bases;

relatively low prices

Plastics can be derived from petrochemicals or from renewable sources (eg bioplastics).In developed countries, almost a third of plastics are used for consumer goods (eg...

Read this article...

Increase productivity with Human Interface Mate (HIM)

HIM is an innovative system that transforms workstations into a digital and interactive environment. It reduces the qualitative and productivity variations in the manual processes by guiding the operator, thus being a poka-yoke system, ie a process in which mistakes due to the human factor can be prevented.Transforming workstations into a digital environment is done by:

Operator guidance with augmented reality instructions

Validation of operations by built-in smart sensors

Integrating...

Read this article...

FlexSim - software for analysis and 3D modeling of processes and systems

FlexSim is software that helps you turn your existing factory data into accurate predictions for your organization in order to analyze a current or future scenario.The 3D simulations created with FlexSim help you mimic the look of the real system, so it is easier to understand and evaluate based on data happening in current processes or designed for optimization.This allows you to identify potential bottlenecks in the process or system and the optimal location options to eliminate them.FlexSim...Read this article...

Who is responsible for PFMEA?

Responsibilities within the organizationWhen an organization decides to use the PFMEA methodology one of the first questions that arise is about responsibility for the process… and usually after this time the organization gets stuck in a long series of negotiations in the management team, usually between the engineering and quality departments.The ambiguity arises from a poor understanding of what this responsibility means or because of the behavior of that organization in terms of (non)...Read this article...

IATF - remote audits during COVID-19

The spread of the COVID-19 pandemic affected all branches of industry, with automotive production being one of the hardest hit.In addition to the existing problems in 2019 with the availability of labor and the decrease of orders, there was also a less known and discussed issue, the conduct of audits in pandemic conditions.Due to the pandemic, many organizations were forced to discontinue their activities for a shorter or longer period, which in many cases led to the expiry of the IATF...Read this article...

Setting the objectives; SMART

Companies that want to achieve performance need to develop an organizational culture based on goals. And of course these related to performance evaluation for both top and middle management and for individual employees.Starting from the CEO's vision and strategy, the long-term objectives of the company are defined and they are later broken down at the level of the organization's structures and finally at the individual level.The power of goals lies in how they create both an action plan for the...Read this article...

Prioritization; Make the most of opportunities

During the improvement process, after defining the problem, collecting the data and analyzing them, decisions must be made regarding the choice of optimal solutions to be implemented.After finding the root causes, the project team can generate several improvement ideas, only a few of which need to be selected based on an objective assessment.Prioritization is a decision-making, rational process that is achieved through criteria. Most of the times, when the team members find the best criteria,...Read this article...

How much do we plan and how much do we leave (planned) "at random" ?

n our "Production Planning" courses, when we get to the capacity calculation of production capacity and especially how much we choose to fill capacity, many participants have the same frustration: WE KNOW (it is 100% sure) that we will have variations in customer orders , that there are problems with machines and equipment (it does not work at 100% capacity), that we do not have enough operators sufficiently prepared, but we insist on planning at theoretical capacity (maximum). "We know" and...Read this article...

Sampling

Data must be collected to perform analyzes, studies, graphs, or to demonstrate improvements after a project.

Collecting (measuring) a lot of data can sometimes be very expensive, it would require a lot of time and resources. For this reason, we are working with sampling.The sample is a significantly smaller extract of the population used to make a deduction and relate back to the population. Usually the most common deductions are average and standard...

Read this article...

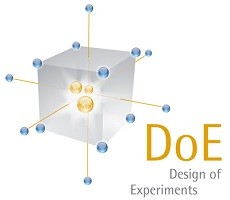

DOE - What it is, and purpose

The study of processes is essential for their improvement. We can observe events as they occur without influencing them. If we are lucky, an interesting event for our process can take place during the observations.If not, then we need to proactively manipulate the input variables so that their effect on the output variables can be studied.DOE (Design Of Experiment) is a scientific method by which, in a systematic and planned way, experiments are performed that allow the evaluation of the effect...Read this article...

COPQ: Non-Quality and Six Sigma Costs

As it is known, Six Sigma is a problem-solving methodology, which improves the quality of products and, consequently, increases customer satisfaction.COPQ means the costs of Poor Quality.Knowledge of COPQ allows an organization to determine the extent to which its resources are wasted.Having such information allows an organization to determine the potential savings that can be achieved by implementing process improvements.There are four categories of quality costs to consider in the COPQ. These...Read this article...

Choosing Six Sigma Projects: A Challenge

Six Sigma projects generally addresses to more complex problems, for which no solutions are known.Initially, when creating the methodology, the vast majority of projects started from VOC (Voice of Customer) and lately, especially in times of crisis, such as the one in 2009, the VOB (Voice of Business) approach was also observed - in fact a reduction in costs.Many projects are chosen from KPI (Key Process Indicators) to be improved.These could be: defect rate, preparation time, equipment...Read this article...

The purpose and advantages of an ANDON system

In Lean production, an ANDON refers to a tool that is used to inform and alert workers about problems in their production process.The term Andon comes from a Japanese word for the traditional paper lantern. An Andon is one of the most common forms of visual management that is used in Lean. It is an extremely effective tool, as it allows the operation to work without problems, without blockages. An ANDON is a system that helps the flow of information on the status of the production...

Read this article...

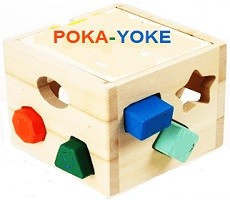

Poka-Yoke concept and benefits

Poka Yoke is a commonly used method in Lean Manufacturing to ensure as few errors in a production process as possible. A "poka" is an "unintentional error" and "yokeru" is Japanese for "prevention", so Poka Yoke is a mechanism that prevents a mistake or makes the mistake obvious at first glance.Poka Yoke is used to prevent and resolve defects during the production process, eliminating the need for quality control after the process.Poka Yoke makes it practically very difficult or impossible to...Read this article...

Preventive maintenance. Important elements for its success

Preventive maintenance (PM) sums up the activities that are regularly performed on an equipment to reduce the likelihood of failure during operation. Basically we want the equipment to work perfectly until the next planned shutdown.Implementing preventive maintenance involves a few steps, namely:

1. Choice of equipment maintenance system

2. Preparation of spare parts lists

3. Supply of spare parts

4. Training of maintenance personnel for the performance of preventive maintenance...

Read this article...

How do we balance workstations ?

Balancing workstations in a production line is used to improve technological flow by reducing worthless activities. The balancing of the line consists in distributing the work as evenly as possible between the stations.The reference time for balancing production operations is the tact time calculated based on the customer's order and available capacity.This type of project is carried out in two stages: evaluating the current situation and preparing & implementing the future situation.For...Read this article...

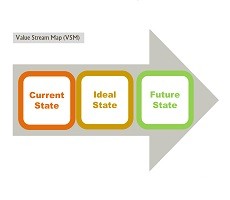

What is VSM / Value Flow Chart and what is it for?

Material and Information Flow Diagrams were originally developed by Taiichi Ohno and Toyota's Operations Management Consulting Division to help suppliers learn the Toyota Production System.Later, in 1999, Mike Rother and John Shook adapted the Toyota techniques and turned them into what we know as "Value Stream Mapping". Value Stream Map is a visual representation of the process flow and information.

VSM is used to locate where improvement is needed in a stream. Whether it is for...

Read this article...

MUDA (Waste - identification and categories)

The activities are divided into two categories: activities with value (VA) and activities without value (NVA).Dumb / waste is defined as any activity that consumes resources without creating value for the customer.

Besides MUDA, there are also MURA and MURI, but both lead to MUDA.

The first means unevenness / imbalance between operations, in processes. MURI, refers to the overloading of equipment or operators.

Non-value added (NVA) activities can be divided into eight...

Read this article...

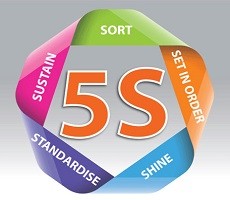

5S - Performance indicator for the Production area

Organizations use multi-level KPIs or performance indicators to assess success in meeting targets.High-level KPIs can focus on overall business performance, while basic-level KPIs can focus on processes in departments such as sales, marketing, human resources, production, maintenance, and more.

In addition to the classic indicators for the Production area such as Efficiency, Productivity or OEE, we must also have 5S.

5S is composed of the following...

Read this article...

Hypothesis Testing: Continuous Output vs. Attributive Input

Sometimes, in practice, we want to make sure we make the best decisions. For example, we want to choose for deliveries in the city, the fastest option between scooter and van.We will use hypothesis testing, a method of proving beyond any logical doubt that a statement is true or not.A number of statistical tools are used for data analysis, the application of which depends on the type of input and output data.We issue the null hypothesis (H0): The delivery time is the same for both means of...Read this article...

The link between FMEA & Control Plan

Common mistakes that impede performanceAre we conscientious users of the FMEA and the Control Plan and still have problems? Then we should be careful that:1. The FMEA should be aligned with the Control Plan process steps.The process steps must correspond to those defined in the Flowchart. Each line in the FMEA must have a corresponding line in the Control Plan, more precisely for each risk identified in the FMEA we must have a control for prevention or at least detection in the Control Plan.2....Read this article...